Catalytic pyrolysis

Pyrolysis is a thermal decomposition process carried out in an inert (oxygen-free) atmosphere. Under the effect of heat, polymers degrade into gas, liquid and solid phase products that can be valorised in the chemical and energy industries.

Pyrolysis is an effective solution for the treatment of polymer and polymer-based composite waste that cannot be processed by conventional mechanical recycling.

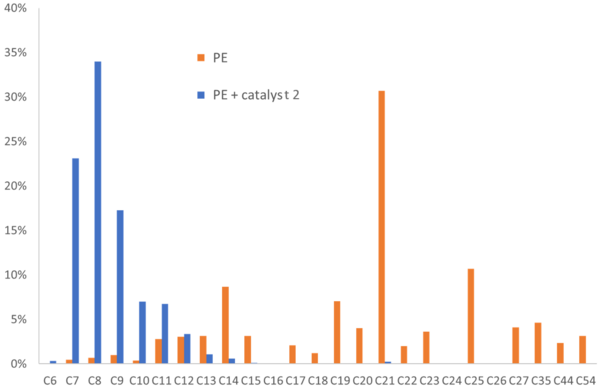

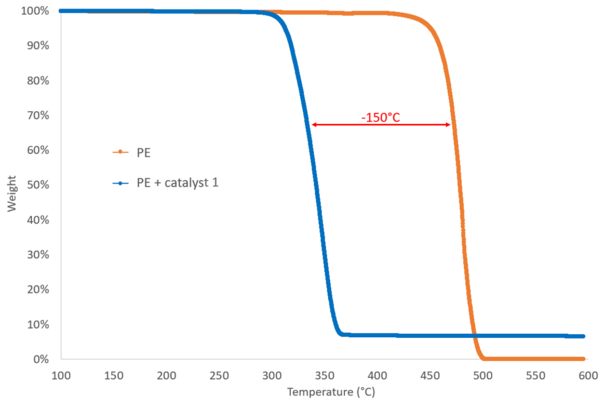

Depending on the experimental parameters and the catalyst used, it is possible to adjust the selectivity of the products obtained. Some catalysts can also be used to reduce the pyrolysis temperature, thereby improving the process energy efficiency.

Regarding catalysts, POLYREC relies on the knowledge acquired in recent projects, and works also with the academic laboratory UCCS (Unity of Catalysis and Chemistry of the Solid) on certain projects.

We currently have several experimental set-ups for this process:

Flash pyrolysis tubular reactor (Tmax 800°C). In addition to continuous gas flow, this reactor enables higher temperatures to be reached and reactions to be carried out in flash mode. Indeed, it is designed with a cold chamber at the tip for rapid introduction of the sample into the reactor.

Fluidised bed reactor (currently being implemented as of 09/2024): This type of reactor, thanks to the constant agitation of the bed, provides a homogeneous distribution of heat and improves material/catalyst contact. It operates continuously with a regular supply of material, making it more flexible and better suited to the requirements of industrial processes.

Please find below our latest publication on the subject, available in Open Access:

In addition to the experimental set-ups already in place, our team regularly develops and invests in new set-ups and instruments to meet specific needs.

So do not hesitate to contact us to discuss your specific requirements.